On a blustery, rainy afternoon, I sat down with Tre-Fin Foods

in their annex while the wind and rain pounded on the windows. “There are three things

that a sea- food distributor must have nailed down to be successful in their

endeavors,” says Mike Domey- er, owner of Tre-Fin Day Boat Tuna in Ilwaco,

WA. “First and super important is water access, without which you can’t

move your product ashore. Second is a stable supply of ice. Third is cold storage

facilities near your market area.” Since 2014, Tre- Fin has utilized varied

solutions to meet these requirements,

Domeyer and his company have recently acquired new building space a short

distance away from the Port of Ilwaco waterfront. The building, in the city of

Ilwa- co, having formerly housed the infamous "Sea Hag" bar, stood

vacant for several years. After an extensive remodel, they now process the daily

catch of their own three fishing boats and the other eight boats of the fishing

fleet that comply with Tre-Fin’s live-catch standards.

“I don’t want to sound sanctimonious,” said Domeyer. “We

are serious about providing a substantially superior product that is transparent

to our cus- tomers and employees and that is also responsible to the avail- able

resource.” All the fish that are brought to their processing plant must

be bled immediately after catching, cooled, and held in an ice slurry while aboard

the fishing vessel. It's called a “day boat” fishery because the

fish must be back to the dock and off- loaded within 24 hours of being caught. “Because

we are fisher- men too, and personally process each fish, we know the differ-

ence and can identify when our standards haven’t been met,” he continues. “You

really can tell the difference.”

In off-peak months Tre-Fin em- ploys eight workers that nearly doubles during

peak seasons. They process Sablefish, Rock- fish, Cabezon, Lingcod, Alba- core

Tuna, Halibut, Salmon and also offer Dungeness Crab. Their current clientele

makeup is about 15% members of their Commu- nity Supported Fishery (CSF); 25%

Farmers Markets in the Port- land, OR. area; 40% restaurants; and the remaining

20% out of their new retail space in their process- ing facility on 1st Ave,

downtown Ilwaco. Their website is at https:// trefinfoods.com/. There, you may

also mail order their value-add- ed products like smoked fish and spreads in

addition to their hand cut, quick-frozen, vacuum-packed selections of fish.

Over the years Tre-Fin has bene- fitted from Ecotrust, Portland, and the USDA

Value-added Producer- Grant program where they were encouraged and coached on

how to generate new products, create and expand marketing opportuni- ties, and

increase income oppor- tunities.

Tre-Fin’s "dayboat" moniker

is getting noticed up and down the coast as consumers recognize the resultant

differences in the taste, firmness, and shelf life. Domeyer claims that virtually

no one used the term “dayboat” back in 2014. But ten years later

he sees it being copied in select fisheries in Ore- gon and California.” Tre-Fin’s "dayboat" moniker

is getting noticed up and down the coast as consumers recognize the resultant

differences in the taste, firmness, and shelf life. Domeyer claims that virtually

no one used the term “dayboat” back in 2014. But ten years later

he sees it being copied in select fisheries in Ore- gon and California.”

Editor's Note: Tre-Fin is actively recruiting individuals with

restaurant sales experience to expand its reach to the Greater Seattle region.

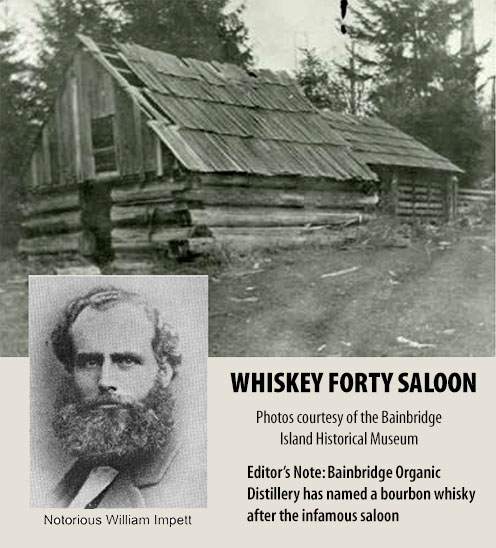

NO SHORTAGE OF SALOONS DURING

BAINBRIDGE’S EARLY YEARS

—

Whiskey Forty Saloon - One of the Most Notorious

—

Although Eagle Harbor was pretty “dry” during the latter 1800’s

mainly due to the efforts of outspoken teeto- taling settlers Riley Hoskinson

and Am- brose Grow, the rest of the island was no stranger to strong drink.

In the sawmill town of Port Madison, on the island’s north end, one could

only get beer at the town’s hotel. On the outskirts of town several whiskey “farms” were

well known by the mill workers. The most notorious of these backwoods still and

saloon operations was known as “Whiskey Forty”, owned by William “Bob” Impett.

Pictured below, it sometimes was de- scribed as a two-building establish- ment.

The Forty was built teasingly close to the sawmill property on 40 acres near

the northwest intersection of present-day Sunrise Drive and Tor- vanger Road.

While the mill was suc- cessful in fining or shutting down other liquor establishments

built or floated near the town, the Forty seems to have thrived for quite a while.

Impett (inset) was born in Pennsyl- vania in 1834 to English parents. He was

sent to England to attend school. He ran away to become a shipboard cabin boy

and sailed for Australia. Once there, he jumped ship to make his fortune as a

gold miner. When he arrived in Puget Sound sometime pri- or to the 1860s, Impett

was reported to have been lugging pouches stuffed with gold.

He married a Native American woman but left her her for 18-year-old, Helen Buist,

in 1878. Impett had several run- ins with the law and his legal battles were

well recorded in county records. The year 1888 appears to mark his exit from

Port Madison.

|